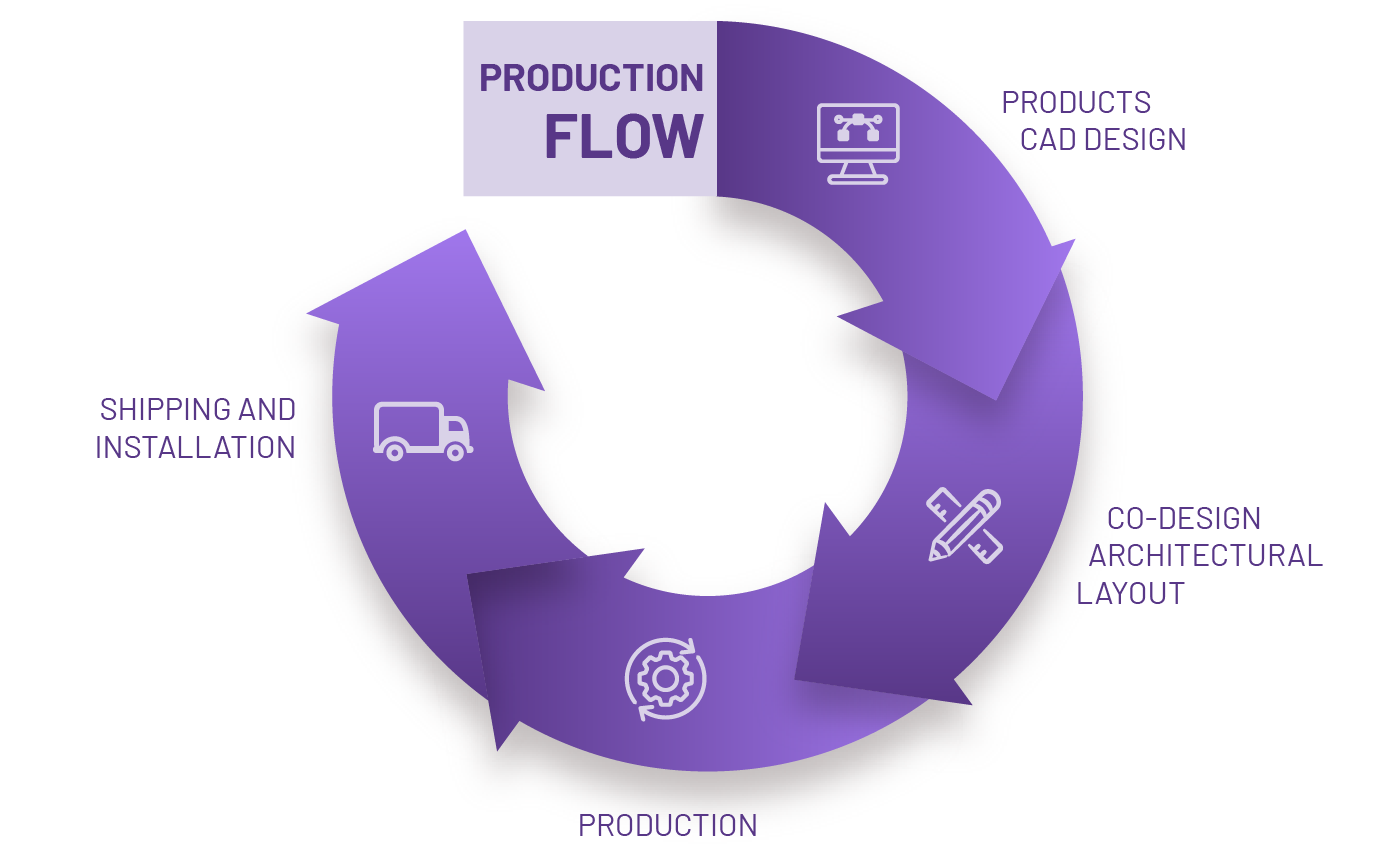

Production

With an unwavering focus on innovation, ROCAM has enthusiastically embraced the fourth industrial revolution, channeling investments into research and development to craft equipment that is not only increasingly efficient and productive but also sustainable. Among the technological advancements is the adoption of the Galileo TP gas charging station, a testament to ROCAM's commitment to leveraging cutting-edge solutions for heightened efficiency and safety. Bolstered by automation 4.0 features and certified quality assurance, ROCAM stands poised to raise the bar for production standards and optimize workflow management. All metal components of our steel articles and models are crafted within our facility, specializing in high-precision metalworking. The expertise and specialized skills of our staff ensure the production of large quantities with meticulous attention to detail for each individual piece. The pride of our metalworking department is the state-of-the-art Amada fiber laser, capable of communicating with other machinery in the department. Our carpentry department is equipped with highly industrialized machinery that allows for processing both solid wood and laminated wood. In particular, our Biesse vertical drilling and milling machine with 4.0 connectivity can coordinate production activities synergistically with other woodworking machines. The assembly phase is one of the most delicate stages of the entire production process: it is the moment when the wooden components, made with high-quality materials and crafted with care, are joined to the iron structure of our products. Once the structure is assembled, refrigerator or heated plate motors, electrical systems, and lights are installed. This step is also carried out with the utmost care and precision to ensure a safe and reliable product. We love to embrace new technologies to keep evolving, which is why we have implemented the Galileo TP gas charging station. This cutting-edge machinery allows us to achieve ten times greater production efficiency compared to the past. Furthermore, it ensures maximum safety for both operators and the surrounding environment, thanks to an automatic control system that detects any anomalies. The gas charging station is also equipped with automation 4.0 features, enabling automatic program recall and gas charge logging, thereby improving workflow management and reducing errors.

Production

Industry 4.0

Moreover, the introduction of the Amada fiber laser and next-generation vertical drilling and milling machine underscores ROCAM's steadfast dedication to innovation and environmental stewardship.

Metal working

Rocam carpentry

Assembly

Gas charging station